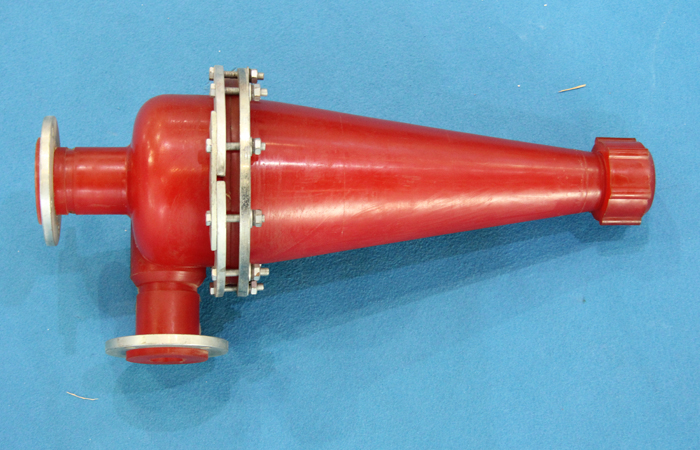

What is the most important spare part on a desander or desilter? The answer is the hydrocyclone. The hydrocyclone on a desander is generally 8-10 inches, and hydrocyclone on a desilter is 4-5 inches. It is made of polyurethane and cast iron. The hydrocyclone is composed of overflow pipe cone drip nozzle and other parts, including: controller, feed gauge, over flow bend, two bolt clamp, cone nut, cone apex, cone body, etc.

Hydrocyclones separate solids or different phase fluids from the bulk fluid. A hydrocyclone comprises a cylindrical shaped feed part with tangential feed; an overflow part with vortex finder; a conical part with an apex. A hydrocyclone has no moving parts.

Product is fed into the hydrocyclone tangentially under a certain pressure. This creates a centrifugal movement, pushing the heavier phase outward and downward alongside the wall of the conical part. The decreasing diameter in the conical part increases the speed and so enhances the separation. Finally, the concentrated solids are discharged through the apex. The vortex finder in the overflow part creates a fast rotating upward spiral movement of the fluid in the centre of the conically shaped housing. The fluid is discharged through the overflow outlet.

Brightway is the professional hydrocyclone desander manufacturer and exporter in China. We can manufacture hydrocyclone with the sizes of 8″, 10″, 12″ and 14″ for Desander for oil drilling mud system and 14″~20″ hydrocyclone for Desanders for micro-tunneling separation plant. And cyclone desanders and desanders without bottom shaker in different capacities can also be provided.