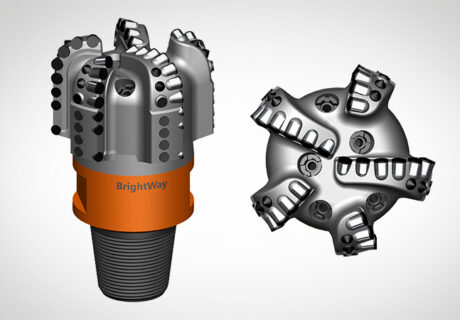

Brightway can design and manufacture 3.5″-17.5″ inch PDC drill bits, PDC drill bits and other specifications of polycrystalline diamond compact drill bits. Using high-performance cutting teeth and high-quality TSP polycrystalline diamond compact, it has high drilling stability and a long service life.

PDC drill bits (polycrystalline diamond compact drill bits) are widely used in drilling engineering due to their advantages of fast drilling speed, long service life, no moving parts, and bottom hole safety. Brightway designs and produces PDC drill bits with specifications such as 3-1/2 “(3.5 inches), 6-1/2” (6.5 inches), 8-1/2 “(8.5 inches), 12-1/4” (12.25 inches), and 17-1/2 “(17.5 inches), using high-performance cutting teeth and high-quality TSP polycrystalline diamond chips, which have high drilling stability and long service life.

Brightway PDC Drill Bit Advantages

● Optimized bit profile and cutting st ructure, force balance and anti-whirl design reduce vibration severity while achieving aggression, it creates smoother, effcient drilling.

● Conical diamond teeth at the behind of Φ16mm primary cutters help ploughing formation, which not only prevent the primary cutters from impact damage, but also increase ROP and prolong bit life.

●Computational Fluid Dynamics Similuation and Hydraulics Optimization for better cutter cooling and cutting evacuation to enhance ROP and Bit life.

● TSP Premium cutters for Super Gage Protection: enhanced bit stability, bit life and hole quality.

Brightway PDC Drill Bit Standard Model and Specification

Brightway PDC drill bits cover sizes ranging from 3-1/2 “to 17-1/2”, including: 3-1/2 “(3.5 inches), 6-1/2” (6.5 inches), 8-1/2 “(8.5 inches), 12-1/4” (12.25 inches), 17-1/2 “(17.5 inches), etc. The types of drill bits include: PDC core bits; PDC reaming bits; PDC reamers, etc. The design of the drill bit blade includes 5-8 straight blade blades and spiral blade blades, etc. The PDC drill bit model standard BWS series covers common drill bit parameters.

| Brightway BW Series PCD Drill Bit Model Specifications (3-1/2 “~17-1/2”)(3-1/2″~17-1/2″) |

|---|

| BWS914 | BWS915 | BWS916 | BWS917 | BWS613 | BWS614 | BWS615 | BWS616 | BWS617 | BWS618 | BWS313 |

| BWS314 | BWS315 | BWS316 | BWS317 | BWS318 | BWS319 | BWS934 | BWS935 | BWS936 | BWS937 | BWS634 |

| BWS635 | BWS636 | BWS637 | BWS638 | BWS333 | BWS334 | BWS335 | BWS336 | BWS337 | BWS338 | BWS339 |

| Optional features of Brightway BW series PDC drill bits |

|---|

| B: Inverted eye teeth | D: Used for directional wells | H: Enhanced diameter protection | J: Vibration damping joint |

| M: Motor guidance | RS: Rotary oriented | NC: Nano anti mud coating | V: Mixed teeth |

Application scenarios of Brightway PDC drill bits

Having strong sensitivity to geological formations and usage measures is the key to using PDC drill bits effectively. The selection of appropriate drill bit types for geological formations is mainly based on rock drillability and the complexity of the formation. If selected improperly, it can lead to premature damage to the PDC drill bit. Gravel layers with larger particles and hard strata; Not applicable! The applicable formations of PDC drill bits:

● Medium soft / soft strata

● soft with hard strata

● Large homogeneous strata

BW series 8.5-17.5 inch PDC Drill Bit Parameter (Partial)

■ 8.5 inch PDC Drill Bit Parameter as follow

| Model | 8-1/2″ BW605J (215.9 mm) | 8-1/2″ BWS915(215.9 mm) | 8-1/2″ BWS916 (215.9 mm) |

|---|

| Blade Count | 5 Stright Blades | 5 Sprial Blades | 6 Sprial Blades |

| Primary Cutter Size | Ф13 mm Ф16 mm | Ф19 mm | Ф19 mm |

| Nozzles | 5 Standard Series (SP) | 7 Standard Series (SP) | 6 Standard Series (SP) |

| Gauge Length | 1.5″, Options available | 2.5″, Options available | 2″, Options available |

| Junk Slot Area | 15 in2 | 14 in2 | 12 in2 |

| Bit Connection | 4-1/2″ API REG | 4-1/2″ API REG | 4-1/2″ API REG |

| Length | Make-Up: 11.8″ Overall: 16.1″ | Make-Up: 10.9″ Overall: 15.1″ | Make-Up: 11.8″ Overall: 16.1″ |

| Fishing Neck | Diameter: 6.8″ Length: 5.4″ | Diameter: 6.8″ Length: 4.9″ | Diameter: 6.8″ Length: 5.4″ |

| Recommended drilling parameters |

| Flow Rate | 25~45 LPS | 21~38 LPS | 21~38 LPS |

| Rotary Speed | 60~320 RPM | 60~330 RPM | 60~330 RPM |

| Weight-on-Bit | 20~130 KN | 20~110 KN | 20~110 KN |

| Max. Weight-on-Bit | 150 KN | 130 KN | 130 KN |

| Make-Up Torque | 49.6~51.4KN.m | 16.6~23.7KN.m | 16.6~23.7KN.m |

■ 12.25 inch PDC Drill Bit Parameter as follow

| Model | 12-1/4″ BWS915 (311.15 mm) | 12-1/4″ BWS915 (311.15 mm) | 12-1/4″ BWS6156J (311.15mm) |

|---|

| Blade Count | 5 Sprial Blades | 5 Straight Blades | 6 Sprial Blades |

| Primary Cutter Size | Ф19 mm | Ф19 mm | Ф16 mm |

| Nozzles | 7 Standard Series (SP) | 7 Standard Series (SP) | 6 Standard Series (SP) |

| Gauge Length | 3″, Options available | 3″, Options available | 2.5″ Options available |

| Junk Slot Area | 39 in2 | 39 in2 | 34 in2 |

| Bit Connection | 6-5/8″ API REG | 6-5/8″ API REG | 5.75-4-ACME-2G |

| Length | Make-Up: 13.3″ Overall: 18.3″ | Make-Up: 13.5″ Overall: 18.5″ | Make-Up: 8.66″ Overall: 11.45″ |

| Fishing Neck | Diameter: 8″ Length: 5.2″ | Diameter: 8″ Length: 5.2″ | / |

| Recommended drilling parameters |

| Flow Rate | 38~62 LPS | 38~62 LPS | 38~62 LPS |

| Rotary Speed | 60~300 RPM | 60~300 RPM | 60~300 RPM |

| Weight-on-Bit | 20~160 KN | 20~160 KN | 20~160 KN |

| Max. Weight-on-Bit | 180 KN | 180 KN | 180 KN |

| Make-Up Torque | 49.6~51.4KN.m | 49.6~51.4KN.m | / |

■ 17.5 inch PDC Drill Bit Parameter as follow

| Model | 17-1/2″ BWS916 (444.5 mm) | 17-1/2″ BWS935RS (444.5 mm) |

|---|

| Blade Count | 6 Sprial Blades | 5 Straight Blades |

| Primary Cutter Size | Ф19 mm | Ф19 mm |

| Nozzles | 9 Standard Series (SP) | 8 Standard Series (SP) |

| Gauge Length | 4″, Options available | 3.5″, Options available |

| Junk Slot Area | 96 in2 | 90 in2 |

| Bit Connection | 7-5/8″ API REG | 7-5/8″ API REG |

| Length | Make-Up: 19.5″ Overall: 24.8″ | Make-Up: 17.4″ Overall: 22.6″ |

| Fishing Neck | Diameter: 9.8″ Length: 6.6″ | Diameter: 9.8″ Length: 8.8″ |

| Recommended drilling parameters |

| Flow Rate | 38~62 LPS | 38~62 LPS |

| Rotary Speed | 60~300 RPM | 60~300 RPM |

| Weight-on-Bit | 20~160 KN | 20~160 KN |

| Max. Weight-on-Bit | 180 KN | 180 KN |

| Make-Up Torque | 49.6~51.4KN.m | 49.6~51.4KN.m |

Please Leave Your Request

If you haven’t found useful information about “PDC Drill Bit” from this page, please fill below table for detailed inquiry.

or send the request to our Company Email: brightway@bwwell.com we will feedback at the soonest!