Drilling Fluid Decanter Centrifuge and Pressure Filter are the important solid – liquid separation equipments for disposing drilling mud and sluge.Compared with pressure filter, decanter centrifuge is the new type sludge dewatering equipment.Because of its mature technology, high solid content after dewatering, low energy consumption and Large capacity,decanter centrifuge is the first choice for sludge dewatering and solids control in other country.

Principle Comparison of Decanter Centrifuge and Pressure Filter:

Solid – liquid separation of Filter Press is achieved by using a special filter media and exerting some pressure on objects.To prevent filter clogging,It needs workers to washing and cleaning using high pressure water. thus,High Salary Cost,High water consumption,also easy to cause secondary pollution.

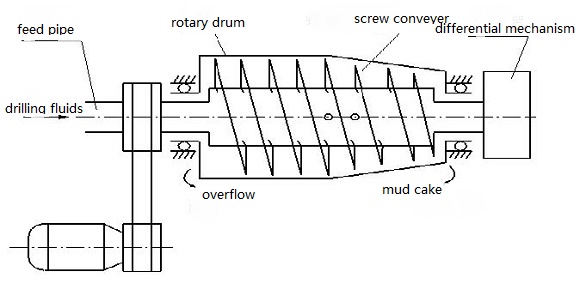

Decanter centrifuge is designed and manufactured according the principle of centrifugal sedimentation.Because of different proportion between mud and water,Decanter centrifuge can achieved solid – liquid separation using centrifugal forces.Since there is no filter that there is no blockage. thus it don’t need to wash frequently and can not cause secondary pollution on the environment.