After the epidemic, drilling projects in important oil-producing areas such as Yan’an and Yulin in northern Shaanxi began to phase out a large number of traditional filter press drill cuttings processing solutions, and instead upgraded and adopted new mud cleaning system drill cuttings processing solutions.

The reason why mud projects are not implemented in Yan’an and Yulin areas in northern Shaanxi is that the traditional filter press drilling tail mud treatment mainly has the following problems:

The filter press cannot work continuously and the efficiency is low;

The filter press needs to be continuously added with medicines, and the cost is high;

The filter press consumes a lot of energy; the processed materials cannot be transported back, and the waste of resources is serious.

Compared with the filter press, the new generation of mud cleaning system has some alternative advantages, mainly in:

The mud cleaning system can realize continuous operation, and there is no need to think that the filter press will be cut off for a certain period of time to affect the project progress;

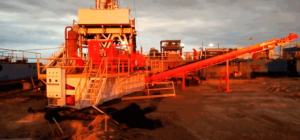

The mud cleaning system can be designed as a vehicle-mounted mobile type, which can realize cuttings processing in several wells at the same time, which greatly improves the efficiency of cuttings processing;

The mud cleaning system does not need to be added, which saves unnecessary investment;

The mud non-grounding system can achieve straight in and out, and the treated water and drill cuttings can be transported back, saving resources and reducing input costs.

At present, many drilling contractors in Yan’an and Yulin areas in northern Shaanxi have begun to consult on technical solutions for mud failure. It has become a trend to replace traditional filter presses with mud cleaning system. In the second half of 2020, many drilling projects will eliminate filter presses, upgrade and configure mud cleaning system for processing while drilling or centralized processing.