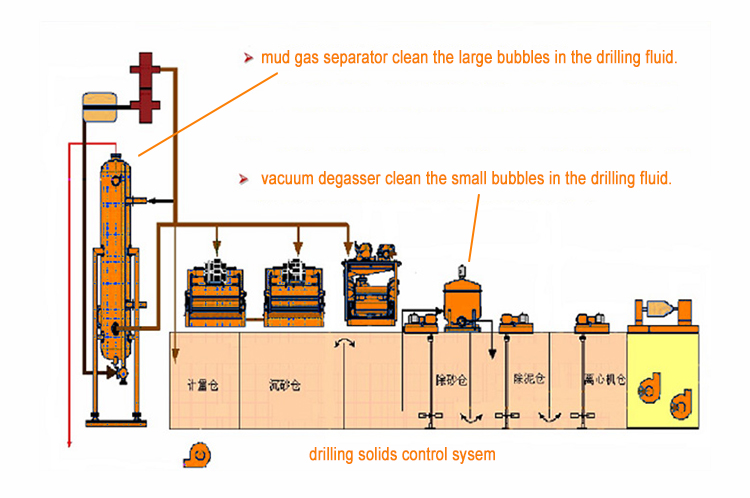

Liquid-gas separators and vacuum degasser are both degassing equipment in drilling solids control systems. What are the differences between liquid-gas separator and vacuum degasser? In fact, the main difference between a liquid-gas separator and a vacuum degasser lies in their different working principles and uses. The liquid-gas separator mainly separates large bubbles in the drilling fluid, while the vacuum degasser is used to separate small bubbles in the drilling fluid; the liquid-gas separator mainly relies on physical principles to achieve gas-liquid separation, while the true degasser requires a motor and a vacuum pump to achieve gas-liquid separation. liquid separation. Please refer to the following points for specific differences and distinctions.

Different Uses Of Liquid Gas Separators And Vacuum Degasser

The liquid-gas separator can clean the large bubbles in the drilling fluid, and the vacuum degasser can clean the small bubbles in the drilling fluid. Large bubbles refer to the expanding gas in the drilling fluid that mostly fills a certain section of the wellbore annulus, and its diameter is approximately 3~25mm. These large bubbles cause well kicks and even eruption onto the surface of the turntable. The liquid-gas separator can feed liquid directly from the rotating blowout preventer or from the throttle manifold to separate large bubbles. There are still small bubbles in the treated drilling fluid. After passing through the vibrating screen, it enters the vacuum degasser for routine degassing. The vacuum degasser is used to remove small bubbles in the drilling fluid, not to remove the large bubbles ejected from the annulus drilling fluid. The main function of the vacuum degasser is to restore the specific gravity of the mud, stabilize the drilling fluid performance, and improve the quality of the drilling fluid.

Different Principles Of Liquid-Gas Separator And Vacuum Degasser

The working principle of the liquid-gas separator mainly relies on physical principles to achieve separation. After the gas-invading drilling fluid enters the liquid-gas separator, it first impacts a wear-resistant steel plate. The steel plate reduces the flow rate of the drilling fluid and prevents wear of the separator body. Then the drilling fluid falls on the specially designed series of inner baffles and flows downward, causing a turbulent flow state to separate the gas from the drilling fluid. Free gas is discharged through the gas outlet on the top of the tank, while drilling fluid is discharged into the circulation tank. The entire gas-liquid separation process does not require any power to operate.

The vacuum degasser uses power supply equipment such as vacuum pump motors to complete the separation of gases in the drilling fluid. The vacuum degasser uses the suction effect of the vacuum pump to create a negative pressure area in the vacuum tank. Under the action of atmospheric pressure, the mud enters the hollow shaft of the rotor through the suction pipe, and then is thrown toward the tank in the form of a spray through the windows around the hollow shaft. Due to the impact of the collision and the separation wheel, the drilling fluid is separated into thin layers, the bubbles immersed in the mud are broken, and the gas escapes. Through the suction of the vacuum pump and the separation of the gas-water separator, the gas passes through the exhaust pipe of the separator. It is discharged to a safe area, and the mud is discharged out of the tank through the impeller. Since the main motor starts first and the impeller connected to the motor rotates at a high speed, the mud can only enter the tank from the suction pipe and will not be sucked in from the discharge pipe.